Custom Asphalt Mixtures

Quality Asphalt Mixtures

that leave a strong, lasting impression.

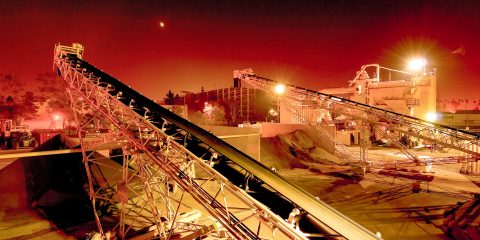

High Volume Plants with Minimal Disruptions

Complex & Custom Mixtures Are Our Specialty

Experienced Quality Assurance Team

Reliable, Durable & Environmentally-Conscious

Safety-Focused Company Culture: Goal Zero

Get high-quality pavement mixtures and service without disruptions.

Sub-standard pavement mixtures and unreliable deliveries throw projects off schedule.

This digs into profits and underscores the importance of picking the right partner.

Excellence in Service

Dedicated experts with 20+ years of experience and relationships you can trust

100 Years Strong

Success in minimizing any delays or plant breakdowns

Your Custom Solution

Our labs rise to meet complex applications head-on

Environmental Care

Using recycled materials and reclaimed asphalt technologies

It’s more than a project to us. We build partnerships for life.

Our superior mixtures with responsive customer service will complete the job without any delays.

Curabitur blandit tempus porttitor. Nullam quis risus eget urna mollis ornare vel eu leo. Duis mollis, est non commodo luctus, nisi erat porttitor ligula.

Mr. NameCompany / Title

Curabitur blandit tempus porttitor. Nullam quis risus eget urna mollis ornare vel eu leo. Duis mollis, est non commodo luctus, nisi erat porttitor ligula.

Mr. NameCompany / Title

Previous

Next

Work With Us

Stop dealing with downtime and mixtures that don’t meet specifications.

Work with a lasting partner that delivers superior products when you need it.

Schedule a Call

Tell us about your project needs.

Establish a Partnership

We’ll be there for you throughout the project.

Have Peace of Mind

Your mixture will be delivered on-time and on-spec.

Our quality assurance and product consistency is our highest priority.

We leverage our highly experienced staff and responsive customer service team to consistently deliver superior mixtures from our top-tier plant.

It's more than a project to us. We build partnerships for life.